Accelrys Materials Studio Student Software Is Used

Is there any soft ware that I can use for modifying CAU-10-H cif file to obtain MIL-160 cif file.Accelrys Inc. I heard of Materials studio but I donot have license/access to Material studio. The students will be thought to solve the. Accelrys Materials Studio, Glucopyranosides. The tendency to form hydrogen bonding is between 1.63&197 - 3.99&197 of first peak hydrogen bond radius detected from the radial distribution analysis (RDF). Accelerys Material Studio 7.0 software is used as the computational technique in this research.

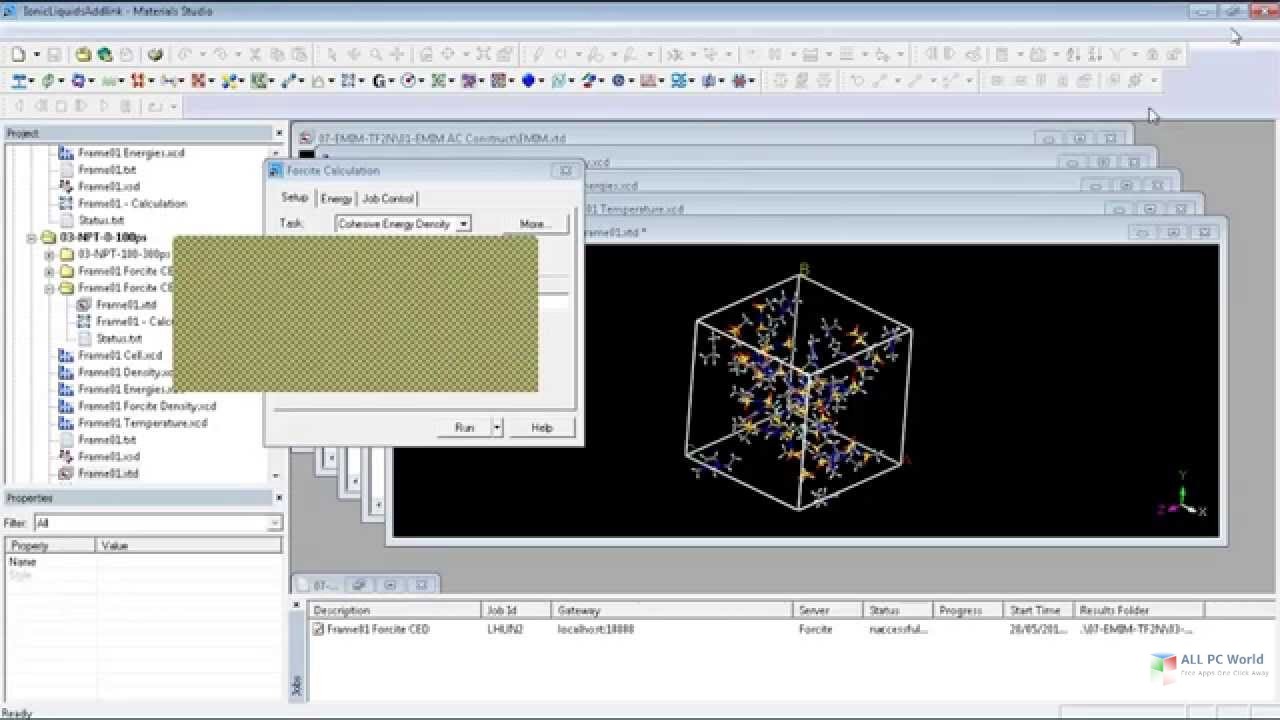

“Materials Studio provides us with the computational science we need to help understand and develop these materials and this release is the most powerful yet.”Materials Studio is software for simulating and modeling materials. “Nanoscience will play a key role in the next generation of materials used in automobiles, aircraft, electronics and many other industries,” says Professor Bjoern Winkler of the University of Frankfurt. Using Materials Studio, researchers in many industries are engineering better. Improved virtual screening of candidate materials and faster property predictions accelerate the development of better performing, cost-effective, environmentally friendly and sustainable materials, minimizing redesign cycles and speeding products to market.BIOVIA Materials Studio is a complete modeling and simulation environment designed to allow researchers in materials science and chemistry to predict and understand the relationships of a material’s atomic and molecular structure with its properties and behavior. State-of the-art modeling and simulation with Materials Studio 6.0 combines the accuracy of quantum methods with the speed of atomistic methodologies. Supporting today’s increasing reliance on micro- and nanoscale engineering, Materials Studio 6.0 enables scientists to relate product performance with material properties and behavior at the molecular and atomic scales.

“P&G’s Purpose is to touch and improve lives, and Siemens is a key enabler in that endeavor.”“P&G is an important, long term client for our business and we are very pleased to have the opportunity to continue to work on the next phase of our relationship,” says Andreas Geiss, vice president, Comos industry solutions, Siemens. I believe Siemens’ robust PLM and Lifecycle Engineering software has helped us secure an engineering competitive advantage to help deliver meaningful innovation to our consumers,” says Irv Kieback, director of engineering in P&G’s Household Care Business Unit. Comos plant engineering software has been in use at P&G since 2009 and is the premier portfolio for lifecycle engineering for complex industries.“Innovation is our lifeblood at P&G. 13.Siemens executives announce a contract extension with Procter & Gamble Co., that will give P&G global access to a wide spectrum of software from Siemens PLM Software, a business unit of the Siemens Industry Automation Division and a leading global provider of product lifecycle management (PLM) software and services, and to Comos, Siemens’ leading global plant engineering software for holistic project assets across the complete lifecycle of an industrial plant and its equipment.P&G has used Siemens PLM Software’s technology since the 1980s and currently has thousands of users deployed across the enterprise. Development of structure-activity relationshipsThe Materials Studio Collection for Pipeline Pilot also automates standard materials modeling and simulation methods for presentation to non-experts in easy-to-use Web browser tools.To learn more about modeling and simulation with Materials Studio, register for the webinar on “What’s New in Materials Studio 6.0,” scheduled for Dec. Property prediction involving molecules, polymers, catalysts and other materials

I'm very pleased that we will now have access to this technology in Canada," says Kieran Murphy, M.D., deputy chief of radiology at University Health Network, Toronto, Canada.According to Millennium Research Group, the global market for Minimally Invasive Vertebral Compression Fracture Treatments (MIVCFT) is poised for growth, due in large part to the aging global population and the large untreated population suffering from painful VCFs treated with ineffective conservative therapeutic measures."Approvals in Canada and Mexico are significant milestones for DFINE and the StabiliT system. The ability to target access and cement delivery while sparing valuable cancellous bone in patients who already have compromised bone structure due to osteoporosis is significant. “P&G’s decision to continue our relationship is a testament to Siemens PLM Software’s effort to continue to provide best-in-class industry-based solutions developed using the knowledge and expertise gained from working with the world's leading CPG manufacturers to address core industry issues and to drive innovation and collaboration.”DFINE Inc., the developer of minimally invasive radiofrequency (RF) targeted therapies for the treatment of vertebral pathologies, today announced that it has received Medical Device License from Health Canada and the Secretaria de Salud (Ministry of Health) in Mexico to sell its StabiliT(R) Radiofrequency Targeted Vertebral Augmentation(TM) (RF-TVA) System throughout Canada and Mexico, respectively."StabiliT represents a significant advance in the treatment of osteoporotic compression fractures.

“While the technologies and materials used for this process have a proven track record in vascular catheter applications, the combination of these technologies in a single component is a hallmark of Putnam’s innovative manufacturing approach.”EyeBrain, a company developing medical devices for the early diagnosis of neurological diseases, announces today that its EyeBrain Tracker device is being used in a clinical trial exploring the dyskinesia induced by treating patients suffering from idiopathic Parkinson’s disease with levodopa.The endpoint of the trial is to find biomarkers for the late-onset complications of a treatment regime using levodopa (BIODYS). It also provides a more gradual transition of the varying durometer outer layer without bonding or hinge points.“Tri-Tie guide catheter shaft manufacturing rethinks the conventional approach to achieve a more integrated and reliable component,” says Ray Rilling, Director of R&D at Putnam. Product performance can vary due to poor bonding between the layers and at the union of the outer layer segments, where hinge points occur.Putnam Plastics’ Tri-Tie extrusion technology eliminates traditional manual assembly of multiple components with proprietary, continuous processing that creates a three-layer composite shaft with maximum adhesion between the layers for improved performance. These catheters are costly and challenging to manufacture due to complex shaft requirements, which include a lubricious inner layer, a braided stainless steel middle layer, and a variable durometer outer layer. Putnam’s continuous technology builds the three-layer composite shafts without manual assembly and staff, resulting in improved product reliability and lower cost.Guide catheters are commonly used to access endovascular sites and deliver balloons, stents, guide wires, contrast media and other devices.

...

0 kommentar(er)

0 kommentar(er)